![]()

By Keith Whiting

Thirty-two miles northwest of Winthrop, Washington, in the valley of Mill Creek, 3 miles northwest of the Cascade Divide is the skeleton remains of the Azurite Mine. This legendary mine was the scene of activity which commenced in 1915, gradually building to a peak between 1936 and 1939, then fading into oblivion.

It is difficult to imagine a more unfavorable setting for mining than the Azurite area. The rugged alpine terrain makes access very difficult and the combination of terrain and heavy snowfall results in snowslides, which pour down almost every small gully with great frequency throughout the winter season.

Charles H. Ballard, through whose perseverance, the Azurite mine became a producer, was no newcomer to northern Washington. He came to the Okanogan district from Butte, Montana, in 1886 as a civil engineer, U.S. mineral surveyor, and assayer. In the next few years he laid out the townsites of Ruby, Conconully, and Chelan, surveyed mineral claims, assayed, and besides all that, served as probate judge.

Later on, in 1898, Ballard, as manager of the Mammoth Mine in Slate Creek, surveyed and built a narrow road over Harts Pass (elevation 6,197 feet). Opened the mine, built a small steam powered stamp mill, and shipped the gold produced from the mine, via the wagon road and steamboat down the Columbia River, until the mine closed in 1901. He then followed mining in Arizona and Nevada during 1904-1906, went to Alaska in 1911, where he was assayer for banks and the U.S. Assay Office. Ballard returned to Washington in 1915 and in that and the following year he, with his brother, Hazard Ballard, and C.R. McClean, prospected in the Mill Creek Valley and staked 31 claims. These claims covered several veins, which are visible on the precipitous slopes and cliffs on the West Side of Mill Creek. The property got its name "The Azurite" from the azure blue mineral, a carbonate of copper, which could be seen in the vein at surface.

Ballard formed the Azurite Copper Co. of Delaware in 1918, with financial support coming from the east. That summer, using hand tools, the Ballards drove a short adit, the Discovery Tunnel (elevation 5,080 feet), to expose the Azurite vein beneath a promising surface exposure. Supplies for this work were freighted 24 miles to the prospect by packhorse from Lost River, a tributary of the Methow River.

In June of that year, H.A. Guess, vice-president of American Smelting and Refining Co., learned about the property through one of the eastern backers of the Azurite Copper Co. Guess then wrote to Preston Locke, an engineer for A.S. and R. in Spokane, requesting him to examine the prospect. In his letter Guess advised Locke that he (Guess) had known Charles Ballard in 1896, when Ballard was a mineral surveyor. Locke examined the property in August and reported that "transportation difficulties are prohibitive." That fall the Ballards were nearly trapped at the mine due to an early snowfall in October. But on the trip out Ballard brought with him the first production from the property in the form of a small bar of gold which he had obtained by grinding ore removed from the Discovery Tunnel, in a small arrastre and recovering the gold by the cyanide process.

During the next seven years a small camp was built. Trenches and pits were blasted to better expose some of the veins. In addition, the Burnam Tunnel was driven 70 feet along the Azurite vein, its portal being 100 feet lower than the Discovery Tunnel.

In April of 1925 the company was reorganized as the Azurite Gold Co., and capital needed for further work was raised by sale of stock. Charles Ballard was president. His brother, Arthur, was secretary. By October 1929 an air compressor, mining equipment, food, fuel and other needed supplies had been either packed or laboriously dragged by horses over the 24 mile trail at a cost of over $100 per ton. During the following winter, the Tinson Tunnel, 200 feet lower than the Discovery Tunnel, was driven several hundred feet along the vein.

In March 1930 the company contacted with the Mace Smelter Co. of Denver to purchase a smelter that would treat 30 tons of ore per day. This smelter was designed to collect the gold, silver and copper in an iron matte which could then be shipped to a conventional smelter for further treatment. During the summer of 1930, the company improved 17 miles of the old narrow-gauge road from Lost River over Harts Pass to Carlson Cabin on Slate Creek (elevation 3,850 feet). And also constructed 11 miles of narrow-gauge road from Carlson Cabin over Cady Pass (elevation 5,980 feet) to the mine site. The use of this narrow road was restricted to small crawler tractors with attached crawler trailers and, to Ford trucks equipped with special lower gears and a wheel gauge cut down to 45 inches. This new road reduced the freight costs to about $20 per ton but, due to long, snowy winters, the road was passable only five or six months a year.

The Tinson Tunnel continued to advance, exposing additional ore, so Ballard elected to drive the Wenatchee Tunnel to explore the vein about 500 feet lower than the Tinson Tunnel. The Wenatchee portal was to be located near the camp, a site relatively safe from snow slides. It was estimated that this tunnel would have to be driven about 1,300 feet to reach the vein.

In 1931 the Wenatchee Tunnel was started and was advanced about 80 feet towards its objective. The Tinson Tunnel was also advanced to a point 1,100 feet from its portal and a raise was driven on the vein from the Tinson to the Discovery Tunnel. The Mace smelter was built that year. During 1932, some ore was removed from the Tinson Tunnel and was treated in the Mace smelter. In 1933 15 tons of matte was shipped to the Tacoma smelter. This shipment contained $2,344 in gold, $8 in silver and $29 in copper.

In the fall of 1933, American Smelting and Refining Co. reappeared on the scene in the person of Louis A. Levensaler, a consulting engineer, who made a brief examination of the mine and relayed his favorable conclusions to ASARCO. Negotiations between Ballard of Azurite and H.A. Guess of ASARCO resulted in an agreement January 2, 1934, on a 25-year lease on 36 lode claims and six mill sites. It called for a $10,000 down payment to Azurite Gold Co. and a 50-50 sharing of net profits after ASARCO had recovered its pre-production investment. The responsibility of conducting subsequent work was assigned to Federal Mining and Smelting Co., Wallace, Idaho, a subsidiary of ASARCO. H.C. Washburn was the general manager of Federal.

In early June of 1934, an advance party consisting of a geologist, an engineer and a cook went on horseback to the property to begin detailed examination. The chief of the party, J.E. Berg, and another engineer followed them, as soon as the road was passable. The examination involved surveying, sampling, geological appraisal and preparation of an inventory of the Azurite Company's supplies, equipment and buildings.

In addition the geologist and a guide made a trip on horseback to Diablo Dam on the Skagit River to determine the feasibility of building an access road from the west. It was concluded that this route was not practicable. The examination of the mine indicated that there were 33,000 tons of ore, which contained an average of .89 ounces of gold and .07 ounces of silver per ton. As the price of gold had increased from $20.67 an ounce to $35.00 an ounce early in 1934, and it appeared that the known ore shoot would continue downward, it was decided that ASARCO would drive the Wenatchee Tunnel to explore the downward projection of the known ore body.

As a result of this decision, Ray E. Walters was appointed superintendent, a crew was assembled, gasoline-powered compressors and fuel storage tanks were installed, mine, machine shop, blacksmith and sawmill buildings were built. Fuel, mining supplies and food sufficient to carry the operation through the winter were freighted to the mine. The Wenatchee Tunnel crosscut contacted the Azurite vein 1,280 feet from the portal and then followed the vein to the south a distance of 490 feet by May 1, 1935, when drifting was halted temporarily.

The following letter by Ray Walters, written to his wife on January 31, 1935, vividly describes the conditions that prevailed that winter.

Dearest Jessie:

I am ready to believe some of the stories they told about winter in the Azurite. As one of our old timers said, "If any of you boys are alive the first of March, you will know I was telling the truth about the weather here."

We had a long cold spell, 29 below and froze our water pipe up and we have to carry our water from the creek up hill through deep snow. We nearly froze to death and I used to put my boots and pants under the bedclothes to keep them from freezing stiff.

It turned warm and started to snow. I never saw anything like it, seven feet fell in two days. It then started to rain and poured down for three days. The old snow was packed hard and conditions were just right for snowslides. They started at once and hell was popping for five days. There was a five-minute interval that you couldn't see a slide running in the daytime or hear one roar at night. Some of the big ones filled the air with snow so you could hardly see. Little slides ran between and against the camp buildings and bigger ones stopped just a few feet above them. Some of the boys got panicky and went to the tunnel and root house to sleep.

Our mine building was demolished and had to be dug out and rebuilt. Another building we are not using was knocked down. The roof on our sawmill caved in from snow load.

When the mail carrier came in he couldn't find the halfway cabin, where he usually stays at night, at all. He said he ate lunch on top of a big slide where he thought it was. A man at the Mammoth Mine where I stayed all night when I walked in last fall was buried. A party went in from Robinson Creek to dig out the body.

Our bull cook (Charlie Graves) stepped out of the kitchen to get a pail of water and was buried in a slide. The cook did not miss him for about ten minutes and after he gave the alarm it took forty-five minutes of digging by the whole crew to find him and get him out.

We are having wonderful mild, clear weather now but the next heavy snow comes there will be some nervous men here.

Love to all,

In June, 1935 Walters was transferred to Mullan, Idaho, to become superintendent of the Morning Mine. Lynn Barry succeeded him. Several new buildings were constructed and those damaged by snowslides the previous winter was repaired. Drifting on the Wenatchee level was resumed and continued to a point 1,270 feet from the crosscut. This drifting demonstrated that the gold values in the vein, at this level, were neither as good or as continuous as they were on the Tinson level. After completion of the drift, a raise to the Tinson level was started and had advanced about one-third of the way by the end of the year.

During the summer season surface geological work was completed. This consisted of mapping the surface geology, examination and sampling of all veins and mineralized showings on the property. This investigation involved some exciting mountaineering due to the precipitous terrain. Also during the summer, the road to the mine was gradually widened and the switchbacks enlarged so those small automobiles could be driven to the mine.

Underground development continued through the winter of 1935-36 and as usual, snowslides damaged some of the buildings but fortunately there were no injuries to the men. It was early in 1936 that the decision was made by ASARCO to put the mine in production. Mine and mill equipment was ordered. A contract for trucking was made with the Stonebraker Brothers of Cascade, Idaho, since they had several trucks in their fleet having a wheel gauge that was 8 ½ inches narrower than normal.

These trucks could negotiate the narrow road to the mine.

An area on the East Side of the valley, opposite the mine portal, was selected for the mill and office site because it was the only place that appeared to be safe from snowslides. Construction of the 100-ton per day cyanide mill began June 2, 1936. A bunkhouse and cookhouse were constructed north of the Wenatchee portal. These were built into the hillside and were snowshedded so that snowslides would pass over them. This was precaution that proved worthwhile as only a few months later a slide covered them completely. Damaged was light and there were no injuries. Two aerial tramways were built. One was to convey ore, in buckets, from the bin at the Wenatchee portal to another bin at the mill. The other was to convey de-watered tailings from the mill to stacking area north of the mill. All of this construction was completed in just five months and both the mine and mill was in operation on Nov. 1, 1936.

Considering the location and the transport problems involved, this was a remarkable accomplishment. The credit should be given to J.K. Jorgenson, the construction superintendent, the mechanics and electricians from Federal Mining and Smelting Co., and the construction crew of about 125 men, most of whom came from the Methow Valley. The pre-production expenditures by ASARCO totaled about $545,000.

Because of the six-month period when the road was closed all supplies had to be hauled in and stored for later use. These included 150,000 gallons of diesel fuel, coal and food for at least 70 men.

The food was dried or canned, except for six cattle and six hogs which provided some fresh meat. These animals were housed in a barn, fed, and then slaughtered as needed or when their feed was gone. The cooks baked bread and bakery products. Needless to say, the first truck arriving in the spring loaded with fresh vegetables, fruit and meat was greeted warmly.

The communication problem was solved in two ways, by dog team and by radio. The dog teams, hauling sleds, made weekly trips to the mine via the West Fork of the Methow and Azurite Pass (elevation 6,680 feet). Ed and Chuck Kikendall drove the dogs, both from the Winthrop area. The in-bound cargo consisted of mail, emergency supplies and a moving picture film. The out-bound cargo was mail and gold bullion. Short wave radio receiving and transmitting equipment was installed in the Azurite mine office and also in the Federal Mining and Smelting Co. office in Wallace, Idaho. Two daily schedules were maintained through the operating period.

The crew consisted, predominantly, of men from the Methow Valley. Times were not good during that period and the men wanted to work. After brief training they became proficient miners and mill operators.

The bunkhouse in which the crew lived was far from roomy and was filled with double deck bunks. In spite of the cramped quarters the men adapted themselves to the conditions and got along together surprisingly well. Recreation consisted of the weekly movie, pool, cards, reading and hikes when weathered permitted. One Christmas, the master mechanic, Ray Allen, converted an electric drill into an eggbeater and by pooling the available whiskey in camp produced enough Tom and Jerry's to go around, otherwise Christmas would have been just another day.

To provide for emergencies, in case of injury, a man well trained in first aid was at the property throughout the operation.

On December 22, 1936, less than two months after production started, a huge snowslide roared down the gully just south of the mill, ran up the west side of the valley, swung down the valley. It grazed the buildings at the mine portal, crashed into the ore bin, carried it down the valley a hundred feet or so and damaged the cable on the aerial tram to the mill beyond repair. Since no spare cable was available and the road to the mine had long since been closed by heavy snow and snowslides, it was clear that aircraft would be needed to transport new cable to the mine.

Johnson Flying Service in Cascade, Idaho, had a Ford tri-motor plane whose side door was large enough to accommodate a real of cable which could be loaded on its edge. The cable was put aboard the aircraft at the Twisp/Winthrop airstrip on December 28 and the plane flew to the mine over Azurite Pass. On reaching the mine the aircraft was tilted and, on a signal from the pilot, the reel was rolled out the door, falling free to land in the deep snow. Two trips were required, one for each reel of cable. The first reel landed fairly close to the target area, the second almost hit the suspension bridge, which crossed the valley from the mill to the mine. Both reels were undamaged. Since the mine ore bin could not be reclaimed or reconstructed, arrangements were made to dump the mine cars directly into the tram buckets. In a few days, after much hard work, production was resumed. This emergency airdrop was probably not the first in the history of mining, but considering the conditions and the narrow, cliff-lined valley, it was a truly remarkable feat.

The same month, one of the two 400-horsepower diesel engines, driving the generators that supplied power for the operation, was seriously damaged when a connecting rod broke and then knocked a hole in the side of the cylinder casing. It appeared at first that repair of the engine might not be possible and that there would not be sufficient power. A description of the damage was relayed to the manufacturer, who immediately dispatched a troubleshooter to the mine. He and the mine mechanics removed the piston from the damaged cylinder and boarded up the hole in the side of the engine. The engine was able to operate on the remaining seven cylinders at reduced efficiency until the next summer, when the necessary permanent repairs could be made.

In January of 1937, Fred White, a shift boss at the mill, and the son of the manager of the ASARCO smelter in Tacoma, became ill. His symptoms were described over the short wave radio, to a doctor in Wallace, Idaho, who diagnosed the illness as appendicitis and who gave instructions for immediate treatment. As soon as arrangements could be made, a doctor from Okanogan, with all the necessary supplies to enable him to perform an operation, was taken to the mine by dog team. On his arrival, the doctor confirmed the earlier diagnosis but decided that his patient should be taken to Okanogan for the operation. The 16 or 17 hour trip by dog team to Robinson Creek and thence by ambulance to Okanogan was in vain. White did not survive the operation.

During 1937 and 1938 the mine produced continuously from the ore shoot that had been developed between the Wenatchee Tunnel and the surface. During this time, additional exploration was done by ASARCO on the Azurite vein from the existing workings and also a 160-foot tunnel was driven on the Devils Hole Vein. No new ore reserves were found by this work, thus by mid 1938 it was evident that the ore on the Azurite vein above the Wenatchee Tunnel would be exhausted within months, and unless the Monster Vein contained ore, the mine would be forced to cease production. In July a north drive was started from the Wenatchee Tunnel crosscut toward the Monster Vein. The vein was intersected at 995 feet and was followed approximately 170 feet both to the east and west. The vein was sparsely mineralized. Drifting was terminated about the middle of February at the same time that all the remaining ore on the Azurite vein above the Wenatchee Tunnel had been mined.

During the 28-month period of the ASARCO operation, from November 1936 through February 1939, 72,996 tons of ore were mined. This ore averaged 0.426-oz. gold and 0.045- oz. Silver per ton. The direct operating costs averaged $8.25 per ton of ore mined. The net proceeds from the ore were $972,000. ASARCO failed to recover its investment by about $120,000.

The supervisory staff during the operation consisted of William J. Coombe, general superintendent; Percy Burbank, mine superintendent; and Gene Ireland, mill superintendent. Robert B. Austin and Emmert Lindroos succeeded these latter two after the first year. Ray Allen was master mechanic throughout the operation.

The normal operation required about 70 men. The mine worked two eight-hour shifts and the mill worked 3 8-hour shifts each day, seven days a week. Miners' wages were about $5.50 per shift.

Following the termination of ASARCO's operations in 1939, Azurite Gold Co. entered into an agreement with Northwest Testing Laboratories Inc. of Seattle, whereby it was to make a through examination of the property. James M. Orr of that firm and a crew began the examination in May 1939. Orr's report was submitted on June 24. He recommended that all-important outcropping veins be studied and sampled. He also suggested that additional drifting, raising and crosscutting be done on the intermediate levels between the Wenatchee and Tinson levels and that a winze be sunk and a new level cut below the Wenatchee Tunnel to test the downward extension of the Azurite vein.

Following the receipt of the Orr report, the Auzrite Co. entered into a second agreement with Northwest Testing whereby that firm would do the work that had been recommended or suggested by Orr. At the same time, Azurite obtained an option from ASARCO to purchase the mine and mill equipment.

By September 1939, the surface examination of the veins and the work on the intermediate levels had been completed but results were unfavorable. At that same time the winze had been sunk on the vein to a point 120 feet below the Wenatchee level. Between the 30 and 90-foot points, in the winze, the vein contained ore averaging 0.53- oz. Gold. In view of this encouragement the decision was made to deepen the winze to 140 feet and to cut a level (called the 1050 level) and to explore the vein both to the south and to the north.

A small crew did this work on the 1050 level during the following winter and summer. In all, 625 feet of drifting was done on the 1050 level and a raise to the Wenatchee level was completed. This work exposed two small ore shoots, which, according to the estimate made by the Northwest Testing Laboratories engineers, contained 8,300 tons of proven ore, averaging $11 per ton in gold. However, as ore of this value was only a little better than "break even", the Azurite Gold Co. decided not to exercise its option to purchase the mine and mill equipment from ASARCO and not to attempt to continue the operation. ASARCO removed the bulk of its equipment in 1942. Some of the equipment was shipped to ASARCO operations in Mexico and Idaho and some of it was sold to other companies in the Butte and Coeur d' Alene Districts.

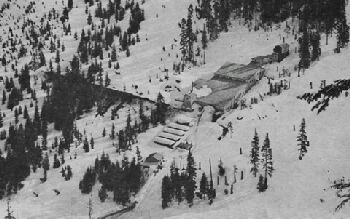

Closely flanked by snowslide chutes is the Azurite Mine mill building as it looked in 1936. Structures shown, from bottom of photo, are: catwalk across canyon, office, fuel tanks, mill and tramway terminal to which 800-pound buckets of ore came from portal to left of camera viewpoint

Ray

![]()